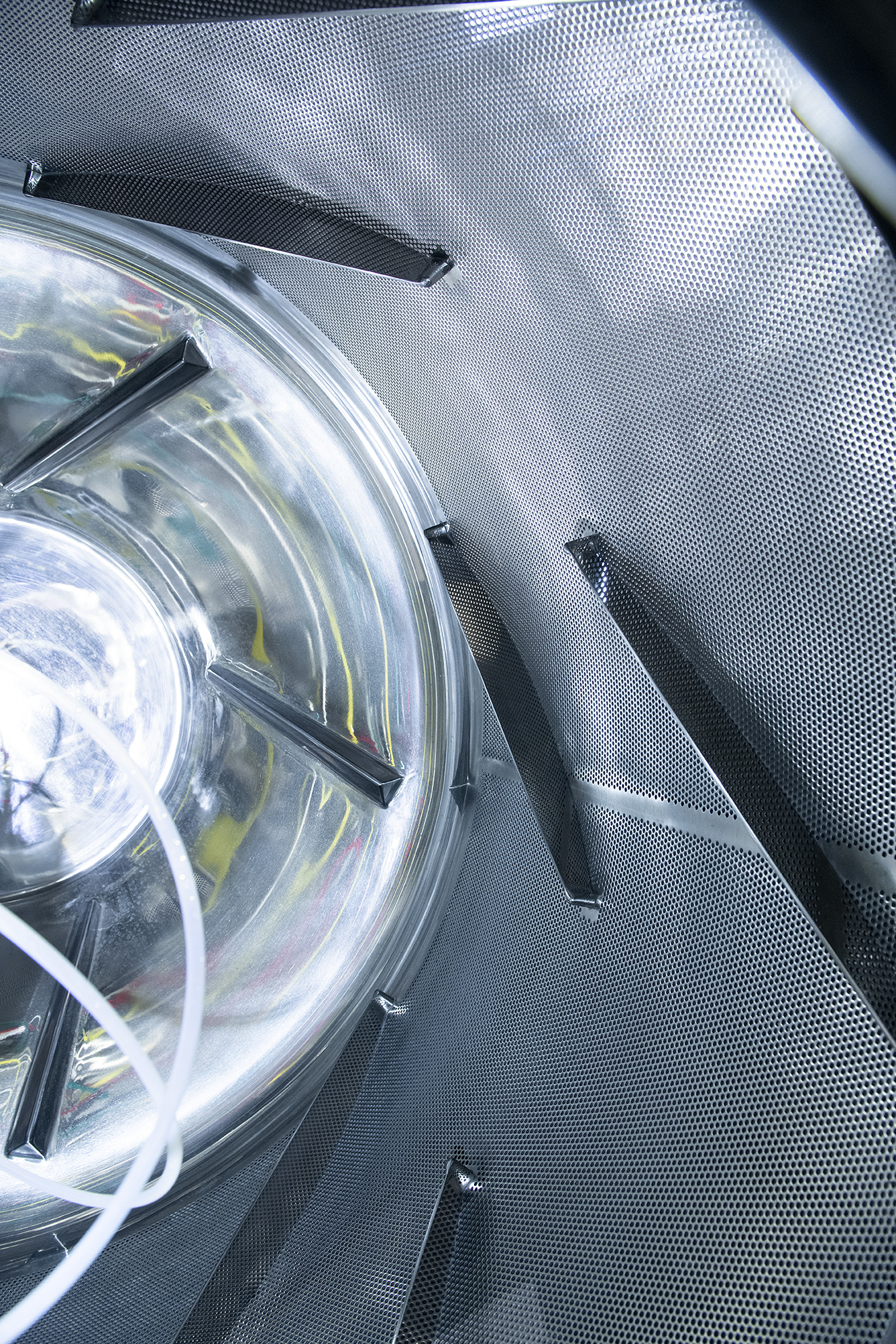

Nicomac Europe created the “Superior” coating machine line with a highly innovative technology. The pan is designed with energized gaskets that ensure water and dust resistance. Schlick spray guns are integrated into the removable and completely adjustuble sliding arm– patent n° 102021000017075. An electric motor allows the system a 20 cm excursion in the tablet direction, in order to modulate the distance between the nozzle and the product bed according to the quantity of tablets to coat. Such distance always has to be between 15 and 20 cm to ensure the best spray uniformity on the whole tablet bed.

The dosage group also includes the atomization and pattern compressed air system regulation, separatedly controlled by micro-filtrated compressed air. This ensures perfect solution distribution and allows homogeneus coating, ensuring maximum output. An optical pyrometer built inside the sliding arm checks the temperature of the tablet bed. Its correct functioning is ensured by a continuous compressed air blow on the lens that reads the temperature.

A Watson Marlow multi-head peristaltic pump adjusts with great precision the spraying solution.

The baffles, Nicomac Europe exclusive design, allow an ensured 15% of total capacity work batch with a perfect mixing that enables to coat tablets that do not meet standard length and friability standards. This gentle and efficient movement eliminates eventual excessive friction or chipping between the tablets. The control system follows the latest generation CFR Part 11 parameters.

The Superior line, available in the PSC and SWC models, with solid or perforated drum, knows no equal in the coating market: thanks to high quality finishings, a modern design and innovative technological solutions, is capable to ensure effectiveness, efficiency and process repeatability.