Cleanrooms design and installation

Every Nicomac Cleanroom represents a perfect balance between efficiency, safety, and people-centric design, transforming work into value.

Nicomac Modular Cleanrooms represent the future in a traditionally conservative sector, standing out for uncompromising quality and a bold vision focused on innovation.

Nicomac Mangini does not merely comply with existing cleanroom standards (ISO 5, ISO 7, ISO 8, and CNC) but dares to push boundaries, redefining the rules with solutions that anticipate future needs. Seismic certified systems, Modular Pharma, and Human-Centered Cleanroom are just some of the innovations we believe will reshape the future of safety and efficiency in controlled contamination environments. Each of our projects integrates cutting-edge design and revolutionary technologies for cleanrooms, tackling problems often not yet recognized by the market but crucial for business success, performance optimization, and the safety of operators and processes.

With a deep understanding of client dynamics, Nicomac creates spaces where innovation and reliability come together, ensuring a tangible and lasting impact.

The cleanroom of the future: safe, hybrid, ergonomic

The extensive expertise developed by Nicomac, particularly in the pharmaceutical and nutraceutical sectors, has made our company an international leader in cleanroom design and installation, with approximately 1,800 completed projects and clients in over 65 countries across various industrial sectors. Nicomac and the Mangini Group are constantly researching ever more efficient solutions to bring real product innovations and tangible benefits to businesses.

Seismic certified solutions

Modular Pharma

Human-Centered Cleanroom

Our products

For nearly half a century, Nicomac has been designing, manufacturing, and installing modular cleanrooms. The integrated and customized modularity offered by Nicomac Mangini ensures versatility, fast installation, quality, and reliability at every stage of the project.

Flexibility and reconfigurability of modular cleanrooms

Maximum mechanical strength and flush integration of cleanroom elements

Complete quality and airflow control in controlled contamination environments

The Winning Formula for Cleanrooms

Industrial Approach: 4 production sites

In-house Manufacturing

In-house Engineering

Modular Cleanroom Systems

Modular Pharma Building

Research & Innovation

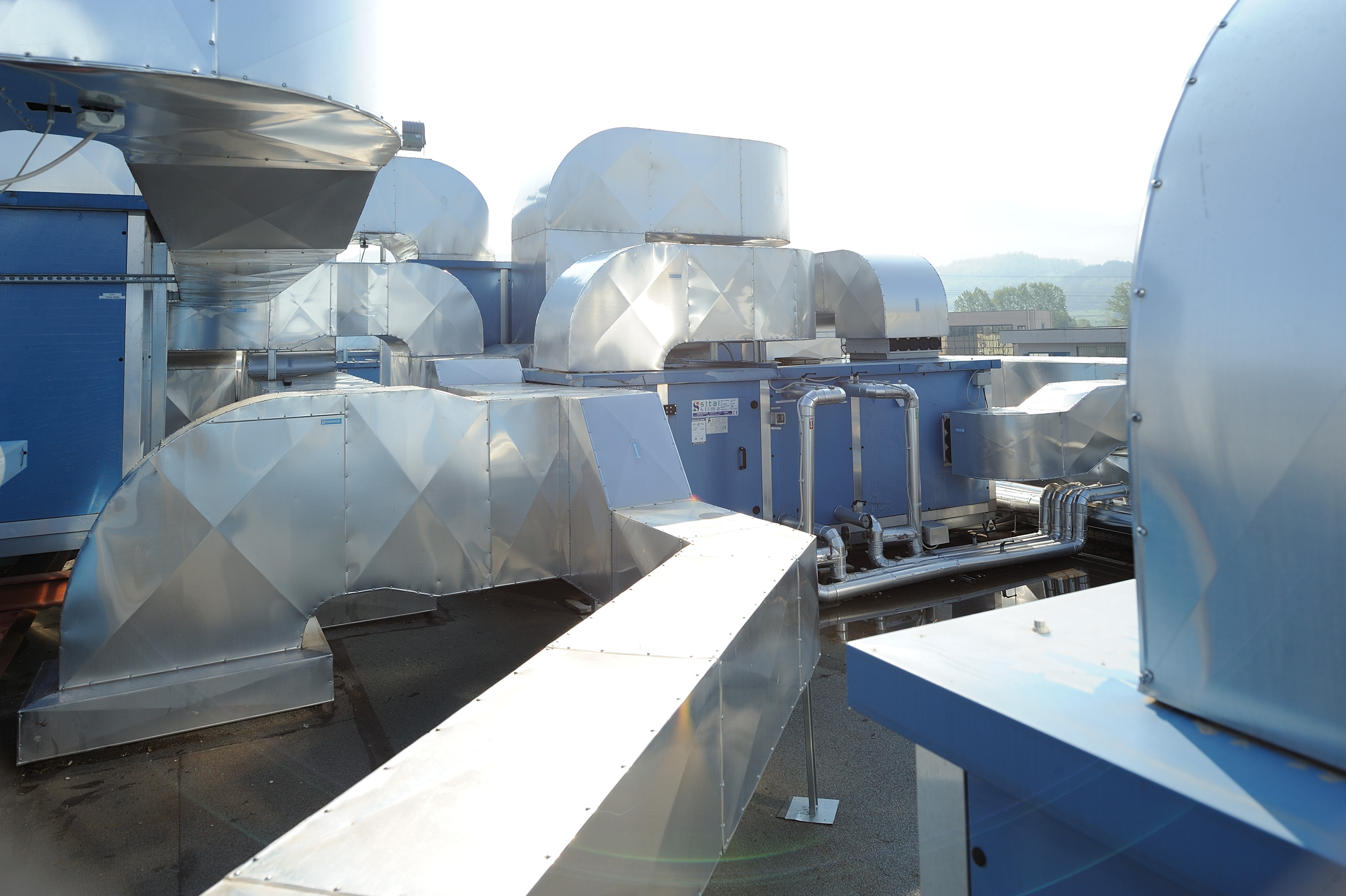

Turnkey Cleanroom Solutions for Controlled Contamination Environments

Nicomac offers a complete and integrated solution for turnkey cleanroom and facility projects. As part of the Mangini Group, our company now boasts over thirty years of experience in managing complex turnkey projects for critical controlled contamination environments. A single point of contact and an industrial partner managing everything from engineering to production, installation, and validation: this is what sets us apart.

BIM-CFD Cleanroom Design

Nicomac Europe uses advanced 3D design systems for cleanroom design, including options for video walk-throughs. Through the use of Revit software, it is possible to visualize how the cleanrooms will be built even before production begins, reducing the risk of mistakes.

BIM - Building Information Modelling

This is the most advanced system for creating and managing information related to construction assets and cleanrooms in the Engineering, Architectural, and Construction (AEC) industries. This process allows for detailed planning of each project phase, verification, and the prevention of potential clashes among all systems on-site, while managing the life cycles of the assets (Structural, Civil, MEP).

CFD - Computational Fluid Dynamics

Implementing computational fluid dynamics simulations in the design of a new cleanroom is the most effective solution for optimizing internal airflow and achieving the required air quality standards. This is done through careful assessment of contamination risks and monitoring the actual effectiveness of air changes. The result is improved performance, reduced energy consumption, and maximum safety.

In its design process, Nicomac Europe uses a highly advanced CFD software to simulate air movement within the cleanroom. This contributes to the development of a ventilation system that avoids turbulence, low airflow zones, areas outside the main airflow, and evaluates the age of the air within the room.

Industries

Tailor-made solutions for the specific needs of every controlled contamination production.

Download the Catalogue

MODULAR CLEANROOMS

Discover Nicomac’s detailed solutions for cleanroom systems in the pharmaceutical, nutraceutical, and life science sectors.

CATALOGUE

NICOMAC MODULAR CLEANROOM

Want to learn more?

Get an rapid feedback to your questions!

Fill out the form to receive a quick and targeted response. Whether you're looking for detailed information, a customized quote, or proposing a collaboration, the Nicomac team will review your request and get back to you as soon as possible.

PART OF MANGINI GROUP

SOCIAL

Copyright © 2025 - Nicomac Srl All Rights Reserved

P.I./C.F.: 07434210964 - SDI: BA6ET11

PEC: nicomacsrl@pec.nicomac.it

Privacy

Preferences

Cookies