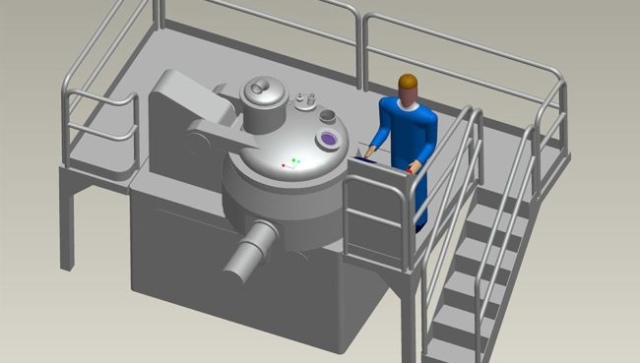

Dry powder mixing, wet powder mixing and granulation can achieve high performance with the Nicomac unique planetary mixer, the “Nicomix™”. Nicomac high shear mixer – granulator can be provided with both automatic and manual dosing system for powders or binding solution.

The Nicomix™ line of granulating equipment combines the 3-blades impeller with a design able to ensure a very good movement of the granules even at low speed. The blade tips of the granulator are positioned tangentially to avoid any dead spots.

The erfect and uniform granulation is allowed thanks to the Tulip design of the bowl that also allows to work from 30-40% up to 100% of the batch size.

The Nicomac rapid mixer design allows a perfect and uniform granulation. It’s easy to validate, clean in place either through a built-in system or through Nicomac CIP-WIP movable Skid ™. Nicomac rapid granulator can be designed to be installed in high containment granulation lines for both R&D labs and production.

- Pharmaceutical execution for cGMP compliance

- Rapid high shear mixer design to avoid mechanical friction with the product

- Granulator dust free loading and unloading operation

- In house Granulators and High shear mixers R&D for your product development

- Excellent powder mixing for granule size uniformity

- All mixers and granulators are equipped with tight mechanical seal

- All Granulators available in large variety of capacities

- Worldwide network for excellent after sales service and fast trouble shooting

- High shear and mixers equipped with state-of-the-art Siemens PLC based control system with touch screen HMI. CFR21 PART 11 software

| Description | Unit | NICOMIX 15 | NICOMIX 25 | NICOMIX 50 | NICOMIX 100 | NICOMIX 250 | NICOMIX 400 | NICOMIX 600 | NICOMIX 800 |

|---|---|---|---|---|---|---|---|---|---|

| Geometric capacity | lt. | 14.5 | 25 | 50 | 100 | 190 | 464 | 600 | 800 |

| Batch max. capacity | lt. | 10 | 20 | 35 | 80 | 150 | 370 | 480 | 640 |

| Batch min. capacity1 | lt. | 5 | 8 | 17 | 37 | 63 | 150 | 200 | 270 |

| Batch max. capacity

(bulk density of 0,5) |

kg | 5 | 10 | 17.5 | 50 | 75 | 185 | 240 | 320 |

| Width with platform | mm | 930 | 1250 | 1400 | 1600 | 2860 | 3200 | 3570 | 3700 |

| Depth with discharging valve | mm | 1478 | 1540 | 2215 | 2640 | 2830 | 3057 | 3367 | 3445 |

| Total height with lid open 70% | mm | 1300 | 1350 | 1875 | 2200 | 2518 | 2750 | 3083 | 3100 |

| Weight | kg | 180 | 355 | 425 | 622 | 1285 | 2100 | 2850 | 3670 |