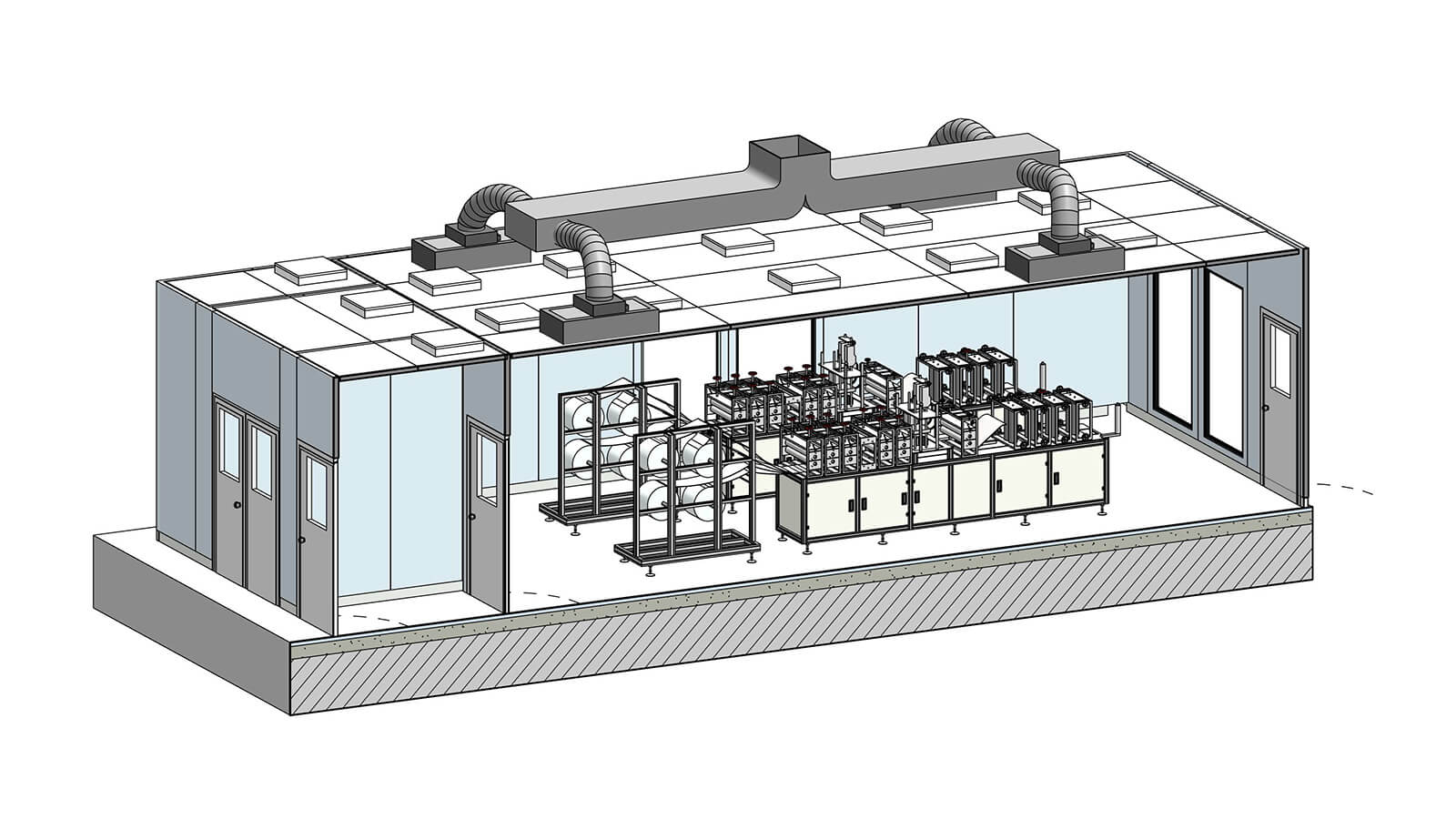

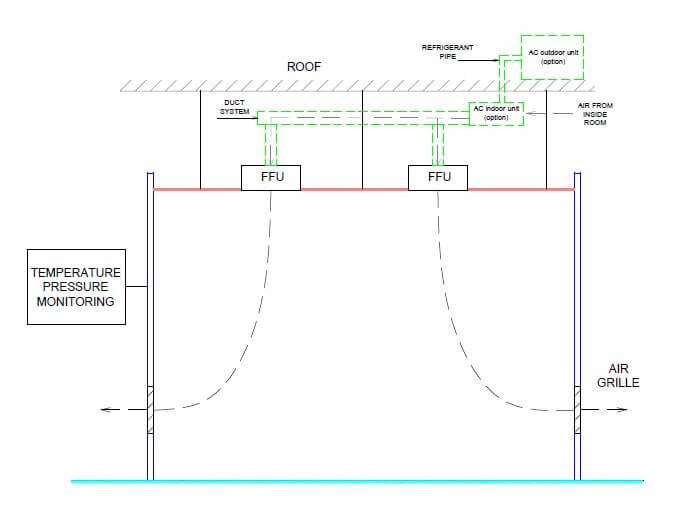

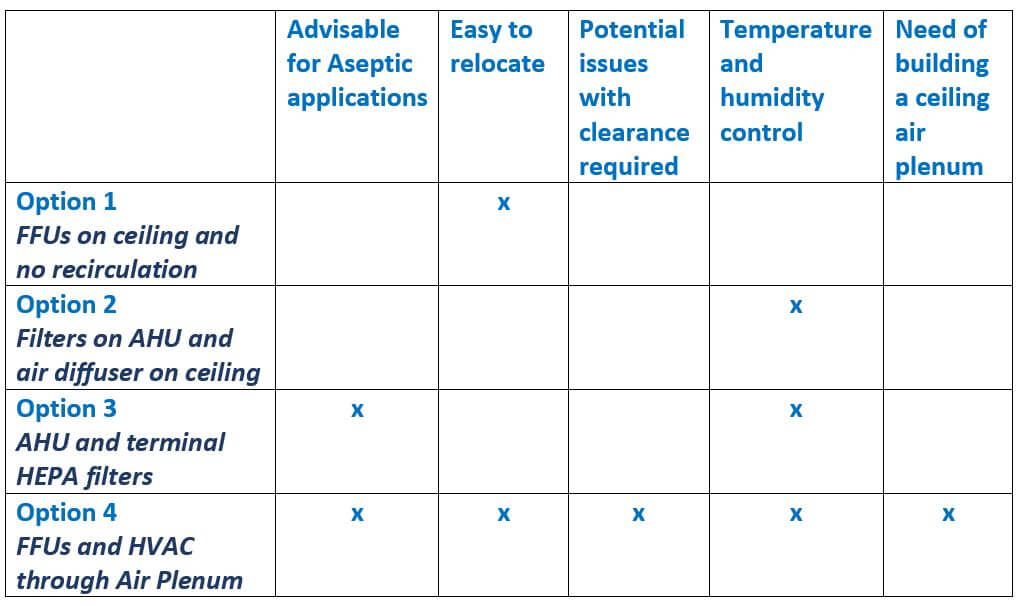

1 – Single-pass cleanroom – FFUs on ceiling and no recirculation

In a single-pass cleanroom, the HEPA filtered air is introduced to the room through Fan Filter Units (FFUs) pulling the air from the open environment (ambient air above the cleanroom ceiling). Once the air flows through the room, it exhausts through low wall air grilles (with adjustable blades to regulate the room’s pressure).

No separate Air Handling Units (AHUs) or ductwork are needed for this kind of design.

This system, because of its simplicity and cost-effectiveness is typically used in smaller cleanrooms with a higher ISO classification. If you are working on a small project, mostly cost driven, without the need to control humidity or temperature (which will depend on the humidity and temperature levels present in the environment where the FFUs take the air from), this is the system that will meet your expectations.

As an option, a single pass cleanroom can be equipped with a small Heating/Cooling unit that can provide warmer or cooler air during summer & winter months, to keep the environment comfortable for the operator. To be used only in small installations

Pros:

- Lower cost

- Quick lead time / faster installation

- Easy to relocate if needed

- Straightforward design

- Highly flexible solution

Cons:

- No humidity or temperature control

- Depending on the heat load, the envirnment might become uncomfortable for the operator/s

- Depending on the quantity of FFUs, the environment might become noisy

- Not suitable for aseptic areas

- Not advisable for large areas

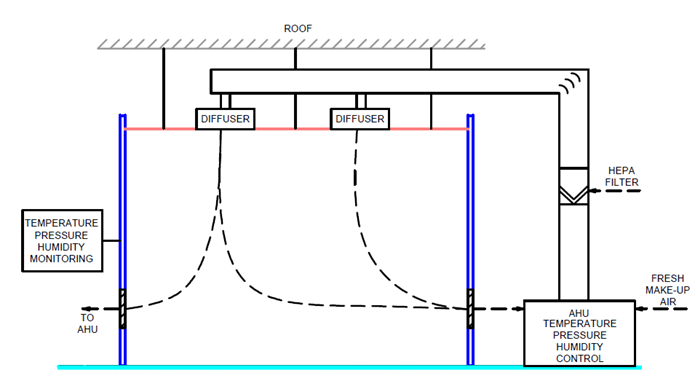

2 – Recirculating cleanroom – Filters on AHU and air diffuser on ceiling

When a straightforward single-pass cleanroom is not sophisticated enough for your requirements, you will need to switch to a recirculating cleanroom. A recirculating cleanroom can be achieved using only one main set of HEPA filters positioned after the AHU unit which, in some cases, can be a vertical unit, requiring less floor space (typically if it is for a small sized cleanroom), and using ceiling mounted diffusers to introduce the pre-filtered air to the room.

Reaching a more stringent ISO class is an easier goal when you are developing your project considering a recirculating cleanroom: the air that arrives to the HEPA units has already gone through several cycles of filtration, and it is likely more “clean” than the regular outside air. On top of that, the system does not have exhausts vents open to the external environment, which makes the whole cleanroom less influenced by external air conditions.

Solution sometime proposed in Europe up to ISO 8, not very common in USA.

Pros:

- Cost effective: only one set of HEPAs, rather than several ceiling installed ones

- Easier HEPA filters maintenance

Cons:

- Not enough filtering capacity: not advisable for Aseptic Environments

- Not advisable for ISO 5

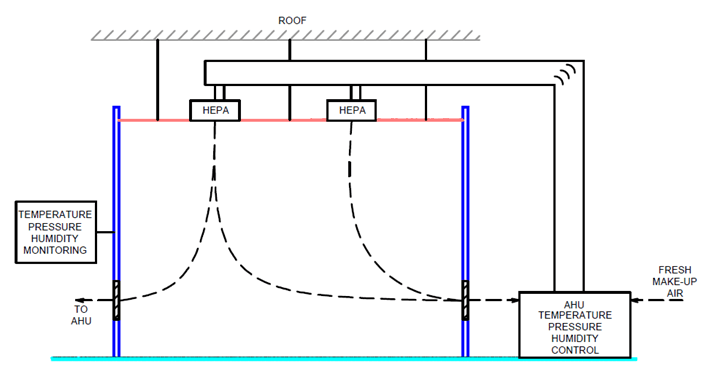

3 – Recirculating cleanroom – AHU and Terminal HEPA filters

If the ISO class of your room is even more stringent, you will need to switch to a system where the drop ceiling is equipped with HEPA filters

With this design, the air is recirculated using a dedicated air handling system and ductwork. The system is then paired with terminal HEPA units installed on the cleanroom ceiling, in lieu of the previously mentioned FFUs or diffusers. Only a percentage of the air is exhausted to the outside environment and replaced by fresh make up air, while the majority of the air is kept in circulation and constantly filtered.

This solution is very popular in Europe for life science applications, where it is considered the state of the art for HVAC systems on FDA or EMA approved cleanrooms

Pros:

- Excellent humidity and temperature control

- Allows design / application flexibility

Cons:

- Higher cost compared to option #1 and #2 and potentially longer lead time

- Not easy to relocate if needed

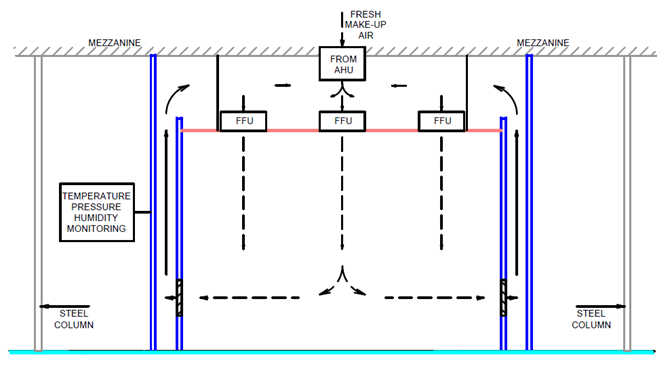

4 – Recirculating cleanroom – FFUs and HVAC through Air Plenum

Another option for a recirculating cleanroom design is the use of a ceiling air plenum.

The plenum is an interstitial space between two ceilings where the air gets recirculated and conditioned (with the aid of an air handler unit), it is then drawn into the Fan Filter Units (FFUs) and the filtered into the cleanroom. This system is designed to recirculate the air through low wall air chases, built within the room, and back to the plenum where it goes through the FFUs again. This might be a good solution if, because of the structural condition of the civil roof, the cleanroom ceiling must be supported by a steel structure designed for the job. The mezzanine can be used to build a plenum and will allow to have a walk-on outer structure without the need of a cleanroom walk-on ceiling which, for some other cleanroom suppliers can be very expensive.

For smaller cleanrooms, this solution is preferred in North America. In Europe, this solution is generally discouraged.

Pros:

- Good humidity and temperature control

- Easy to relocate

- Easier to validate

- No need for ductwork above cleanroom ceiling

Cons:

- The vertical clearance required could be an issue in some buildings

- Higher cost due extra walls and ceiling panels required for a ceiling air plenum

- Depending on the quantity of FFUs, the environment might become noisy

- Potential issues with plenum ait tightness

Conclusions

As it appears clear from the details and pro and cons of each possible solutions for your cleanrooms, the choice among those options is driven by the requirements of the cleanroom such as ISO class, square footage, application, logistics, project schedule and budget. And as it happens in many technical choices in the technical world, these are also made and influenced by past experience, consuetude and general preference of the end user, the appointed designer, or consultant